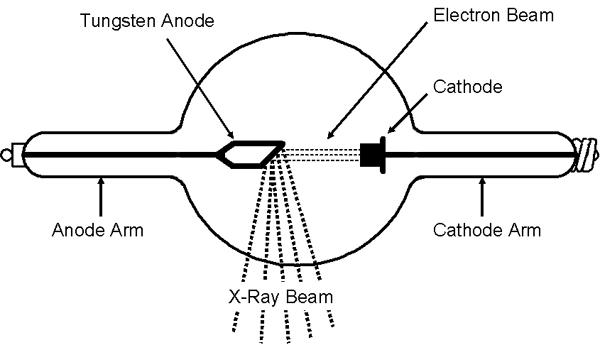

The normal X-ray tube is a vacuum diode. Electrons are generated by thermionic emission from the filament of the tube. The electron stream is electrostatically focused onto a small target on the anode by means of a carefully designed, shaped, and sometimes charged, highly polished nickel cathode focusing cup. X rays are produced by interactions between the electrons and the target.

Most electrons emitted by the hot filament become current carriers across the tube. One can, therefore, set tube current (by adjusting the filament temperature) and tube voltage (by adjusting primary voltage) as independent parameters. Some X-ray tubes function as a triode with a bias voltage applied between the filament and the cathode cup. At low voltage, this bias can be used to modify the size and shape of the focal spot by focusing the electron beam in the tube. A further increase of the bias voltage can serve as a switching device by gating the electron beam ON or OFF.

The X-ray tube converts a very small fraction of the electrical energy delivered to it into useful X rays. In the voltage region corresponding to diagnostic radiology (20– 150 kVp), the physical processes involved in X-ray production (primarily collisional deceleration of electrons in the target) result in an X-ray production efficiency of <1%. The remaining electrical energy is converted into heat. Tungsten is used as the target material for most general-purpose diagnostic X-ray tubes. Its high atomic number maximizes X-ray production efficiency. Tungsten’s high melting point (3400 8C) and reasonable specific heat capacity help with the thermal problems associated with the waste heat. As special cases, molybdenum (Mo), rhodium (Rh), or Mo/Rh alloy targets are used to produce the specific X-ray spectra needed for mammography.

The use of these lower atomic number metals as targets and filters isolates the K-characteristic X rays produced by the target, resulting in a narrow spectral beam at relatively low energy, useful for improving subject contrast in screen-film imaging of the compressed breast. The lower efficiency of X-ray production and lower melting point makes these metals unacceptable for general radiography. Other materials, including silver, cerium, and other exotic materials, continue to be proposed for target materials for specialized applications ranging from small animal imaging to computed tomography and additional industrial applications.

A major task in X-ray tube design is the provision of means for dissipating waste heat before tube structures are damaged. Different tube structures place different thermal limitations on radiographic techniques and ultimately limit the speed of performing examinations. Tube rating charts that account for these different thermal restrictions are available from all X-ray tube manufacturers.

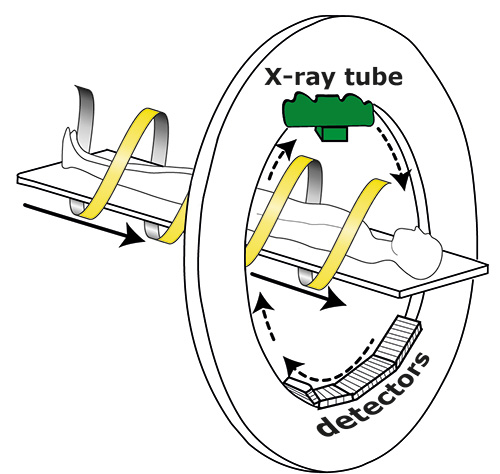

The first consideration is the melting of the tungsten target at the focal spot, the target area bombarded by the electron beam. For sharp projection imaging, the geometry of the X-ray ‘‘optics’’ requires that the focal spot be as small as possible. Design elements such as high-speed rotating anodes (3,000–10,000 rpm) and shallow target angles (58–158) are used to limit the power density incident on the physical target location while creating a small effective focal spot, yielding improved resolution. Effective short-term loading in excess of 50 kW/mm2 of effective focal spot is realized using these techniques. Some tubes even provide userselectable dual-anode angles or dual-position focal spots for increased flexibility.

Once heat has entered the target region of the anode, it is conducted away from the focal track into the bulk material of the anode. This bulk material usually consists of molybdenum or prolytic graphite. Massive anodes (several kilograms) are used to temporarily store the thermal energy before radiating it to the tube housing and eventually into the environment. The large anode mass, needed for significant thermal energy storage (e.g., for applications in computed tomography and cinefluorography), places limitations on the starting time of the tube, due to the moment of inertia of the anode, and on the length of life of the anode’s bearings.

The technical requirement of high anode heat storage capacity is optimally met with a heavy smaller diameter disk. The clinical requirement for short radiographic exposure time demands high instantaneous power levels. This requirement is optimally met with a light large-diameter rotating anode disk. These conflicts result in the design and use of many types of X-ray tubes mechanically specialized to meet specific examination requirements.

The tube housing serves several technical purposes. The housing is part of the electrical isolation between the high-voltage circuits and the environment. It also provides radiation protection for both patient and operator. Tube housings are lead lined to keep the amount of leakage radiation below legal limits (this requirement assures that the major source of irradiation outside of the beam comes from scatter and the useful beam in the patient).

The tube housing illustrated is a variety commonly used, whereby the low atomic number (usually Beryllium) exit window for the X rays is located in the center of the tube between the two poles (cathode and anode) of the power supply from the generator. It is also possible to obtain unipolar X-ray tubes for special applications. With only one single pole for the power supply, it becomes possible to locate the exit window nearer the edge of the tube to allow closer proximity imaging in specialpurpose applications, such as in computed mammotomography.

Also, these tubes are smaller and lighter than standard dual pole tubes. Drawbacks of such tubes include much lower maximum power (i.e., on the order of _100 W to 6 kW, compared with the 100t kW available on other tubes), static anode and, consequently, the need for a larger focal spot to reduce concentration of heat on the anode. These tubes are usually liquid cooled. Finally, the tube housing is a key portion in the wasteheat handling system. Housings for tubes used at low mean power levels (<100 W or so) can be adequately air cooled, with or without a fan. As the mean load increases (i.e., for applications such as angiography and computed tomography), air cooling becomes inadequate. Additional cooling may be obtained by circulating liquid through a heat exchanger contained in the tube housing or by circulating insulating oil through an external radiator.

Price is 8-20% Lower Than Other

Price is 8-20% Lower Than Other